Popular searches:

Ishikawa, Exhibitions, Events

Return to list page

2024/05/11

Pipeline Valve

In the industrial world, every drop of water, every drop of oil, every strand of gas flow is critical. Thus, in the vein of industry, the valve is the indispensable heart, which lies quietly in the pipeline, but carries the important mission of controlling and guiding the fluid. Suzhou Ishikawa Steel, in addition to the production of automotive and rail transportation castings, is also committed to the production of high-quality pipeline valve castings, let's walk into the world of siim's valves.

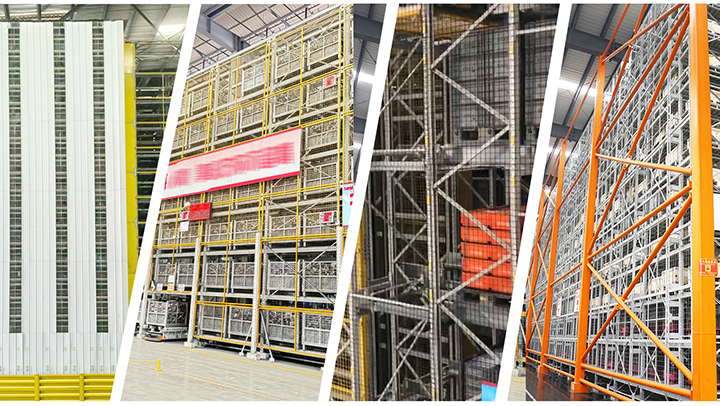

01 Service Clients

We have served customers from Japan's Hitachi, Bomeli vis-à-vis, Denmark's AVK and the United Kingdom's Spiroshaq and other world-renowned enterprises, some have been working together for 19 years. The choice of these partners not only confirms the high standard and reliability of our products, but also the trust and affirmation of our technological innovation and excellent service.

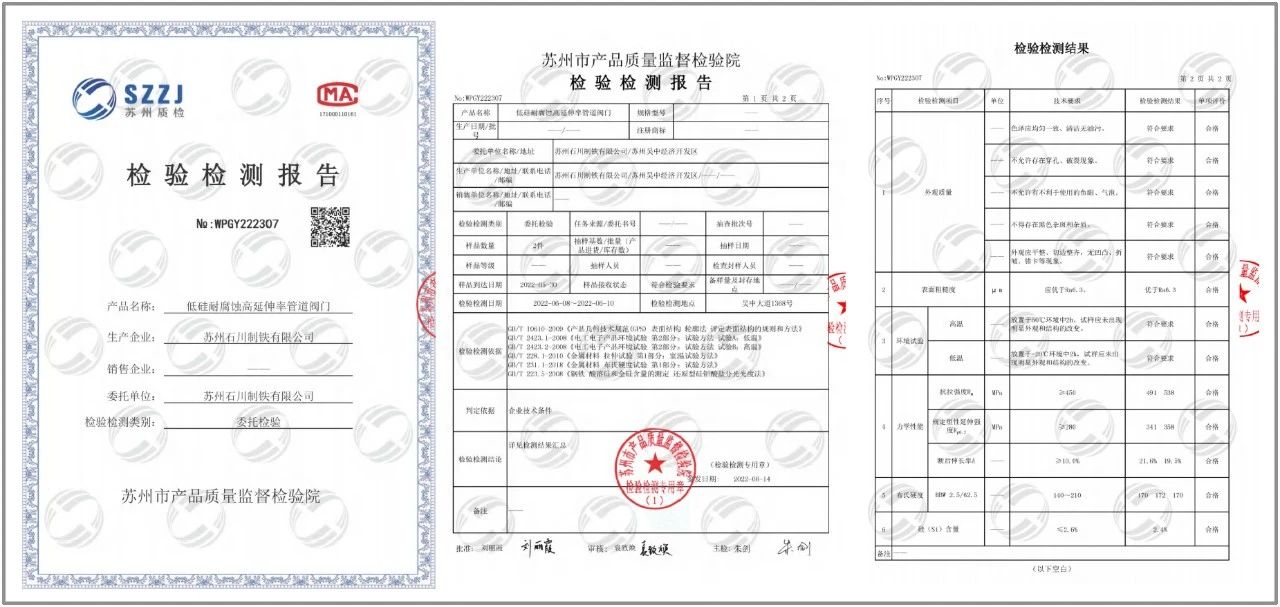

02 Test report and PED certification

This test report is the result of countless days and nights of research by R&D engineers, and is a symbol of quality and trust. It tells us that even in the most severe industrial environment, there can be such a good solution. Choosing this low-silicon, corrosion-resistant, high-elongation pipeline valve is choosing a reliable partner, but also a silent guardian of safety and efficiency!。

03 Product Highlights

The simple shape of this product can be used for both low temperature and low pressure as well as high temperature and high pressure. The low silicon content gives it outstanding corrosion resistance, and it is stable in both acidic and alkaline environments, ensuring long-term sealing performance and operational stability. The high elongation means that it can bend gracefully under pressure without breaking, like a dancer's deft turn on stage, demonstrating flexibility and ensuring structural integrity.

(Silicon content is achieved through process improvement

and control of raw materials and is measured experimentally)

Technical Parameters

Hardness requirement HB:143~187

Tensile strength:>450MPa

Post-break elongation:>18%

0.2% endurance:>320N/mm²

04 Technical level

01 product itself is hollow through the middle, more importantly, the two sides of the flange is big and thick, the wall thickness of the middle product is very thin, such a product single riser technology is easy to produce internal owning, both sides of the double riser technology is easy to produce shrinkage holes at the gate. However, on the basis of adopting advanced casting technology, we flexibly improve and reasonably design the size of the cut-off piece and the position of the risers, so that the problem of the product's internal defects can be well solved.

02 The use of a new type of inoculation with the flow of the device, the device uses the inoculant particles, good fluidity characteristics, through the control of the storage port outlets and flow regulation spindle flow hole is aligned to control the inoculant can be outflow, the size of the amount of outflow by adjusting the flow of the aperture of the spindle to achieve the size of the aperture. The new type of inoculation device with the flow, low production costs and easy to use, avoiding the tedious process of frequent replacement of inoculants and the possibility of different inoculants mixing with each other, greatly improving production efficiency.

03 Rapid determination of sphericalization rate: products with material problems can be quickly determined, and it takes only 30 seconds from sampling to the result.

We are constantly learning and innovating in technology, combining a global perspective with local experience. We understand that every project is unique and every service is a new challenge. Therefore, we are committed to providing our customers with customized solutions to meet their ever-changing needs.

By choosing us, you are not only choosing a valve manufacturer, but also a trustworthy long-term partner. We look forward to working with more forward-looking companies to create a more brilliant future.

In the new working environment, we will continue to uphold the core concepts of pragmatism and innovation, and is committed to providing customers with more excellent products and services...

Each invention patent bears our persistent pursuit of technological progress and our beautiful vision for the future.

There is only one core goal: to ensure that the casting products you ordered are delivered to you faster, more accurately, and more stably!